AFOUR team took part in the international project Hotshop by Ecco Leather

AFOUR Custom founder and designer Vladimir Grigoriev took part in Hotshop, an annual project of Ecco Leather for talented designers from all over the world. Last year, the Hotshop was held in Amsterdam, and this year, due to the situation with the pandemic, the event was held online.

In total, over 100 designers and projects took part in the Hotshop. Last year we took part in a workshop as part of a Russian team, in this one the team was international. Before the start of the workshop, all participants were sent a box containing samples of leather for experiments, examples of technologies - different types of embossing, dyeing, finishing, as well as tools for working with leather. Our package arrived an hour before the end of the event, because it got stuck at customs, but this did not stop us - after all, AFOUR production has everything we need.

Because Ecco Leather is a tannery, the challenge for Hotshop was to come up with a new concept for leather. Every year the company comes up with a common word for the event. This year the workshop was held under the motto "disruption", the destruction of borders: it was necessary to break the rules in order to come up with a new concept. And in the end, this concept will be implemented at the Ecco Leather factory.

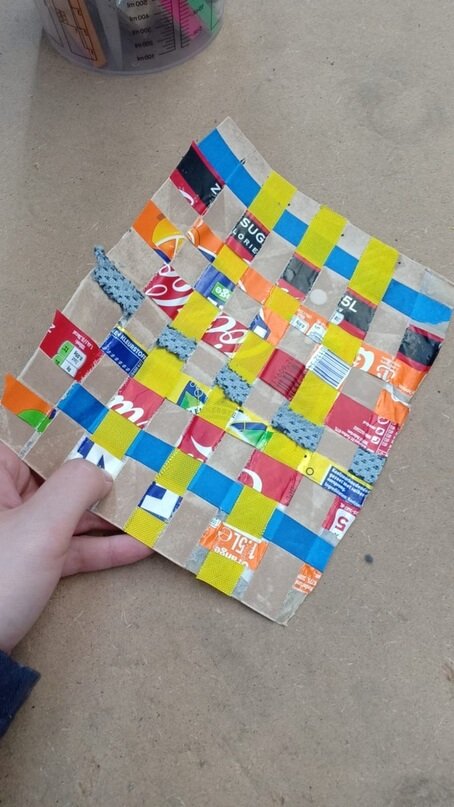

Our team went through the options for a long time and finally settled on the concept of leather using recycled waste. Garbage in Europe has been recycled for a long time, but it is clear that if you have the opportunity to buy a leather jacket or shoes, then you will not buy the same shoes made of recycled plastic. You can buy such a thing for ideological reasons, but you will not get comfort, because natural leather "breathes" and gives completely different sensations on the body. We decided that the combination of recycled waste with a base made of genuine leather would preserve the consumer properties of the leather and at the same time reduce the cost of materials. But it turned out that there is no waste recycling plant where the samples will be produced. Then we came up with the idea of combining leather with debris, turning to the old technology of combining materials - weaving, and then additionally either compressing or chemically treating the resulting material.

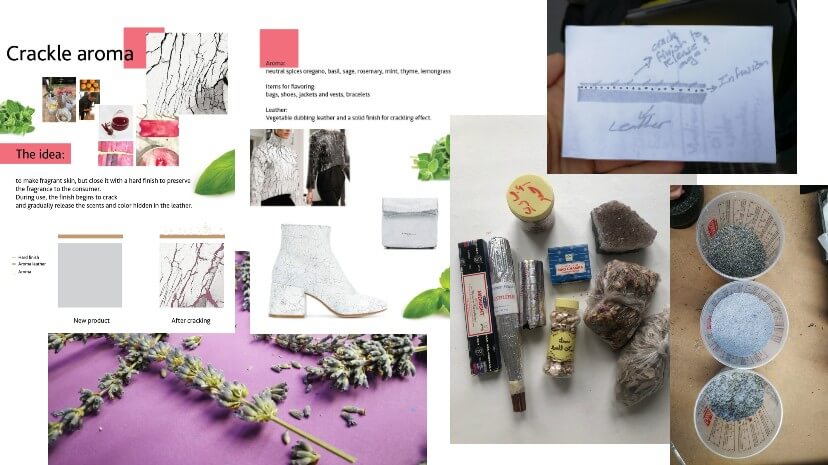

Everyone liked the concept with garbage very much, but after we presented it, the organizers decided to mix the teams so that all participants could work on other people's concepts. So we got into the team that was working on the project of leather that smells like flowers.

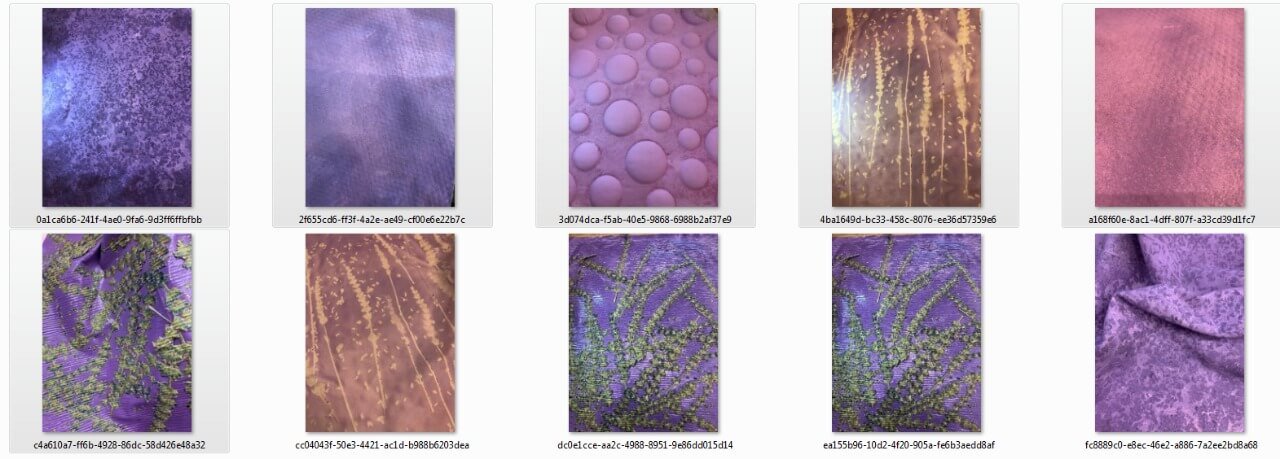

Together we have come up with three variants of the "floral leather". The texture of the first leather was similar to packaging bubbles: you can click on this bubble and get the scent you want, whatever you want. The second leather is two-layer, for sports shoes: we took raw leather as a basis and did a second tanning with floral elements and spices. It remained unpainted, but had the scent of the substances that we added. A layer of perforated leather was added on top: when you move through the perforations, a floral scent comes out. We covered the third variant of scented leather with craquelure varnish: during use, the varnish cracks and lets the aroma pass.

On the second day, we had to make products from this leather. We were given templates - bags, sandals, sneakers, high-top sneakers. We made the design and included the use of different versions of the "floral leather". If last year we had to make samples ourselves, then this year we created leather, filled out the form with the terms of reference and sent it all to a factory in Portugal to a factory.

Many people in Russia are surprised: why do we participate in Hotshop, because our ideas can be stolen? And we are glad if these ideas turn out to be useful and influence the development of the industry. In addition, the Ecco Leather philosophy is very close to us: they use leather so efficiently that nothing remains of it. Historically, tanning leather requires a huge amount of water, and they have no-loss tanning methods that use 10 times less water. All leather scraps are sent to the production of gelatin or biogas. This is a great example of how to intelligently combine tradition with new technologies.

The main trend that the fashion industry around the world is working with today is to do things in order to minimize the negative impact on the environment. The thing must either serve for so long that you can pass it on to your grandchildren, or it must be produced so that over time it disappears without a trace, which means - without damage to the environment.