Sneaker concept in the framework of the graduation project of a graduate of the Stieglitz Academy

It is very important for us to maintain fresh blood in the design of shoes and sneakers in particular. Therefore, we are happy to cooperate with students both in the framework of internships and in helping to prepare graduation projects.

This year we helped Daria Litvinova https://vk.com/litvinovad a graduate of the Stieglitz Academy https://vk.com/stieglitzacademy

Here is her concept:

Conceptual design-project of winter sneakers.

The concept is aimed at creating a fashionable gadget from the sneakers, an accessory that is so desired by modern youth, as well as showing that the fashion for sneakers in the winter can be safe and practical.

A battery and a heating element are built into the sole of the sneakers, to charge the sneakers you just need to put them on the charging station, which is additionally packed in a waterproof case. Upon returning from the street, the sneakers are dried and charged automatically.

According to her sketches, we made a model of future sneakers.

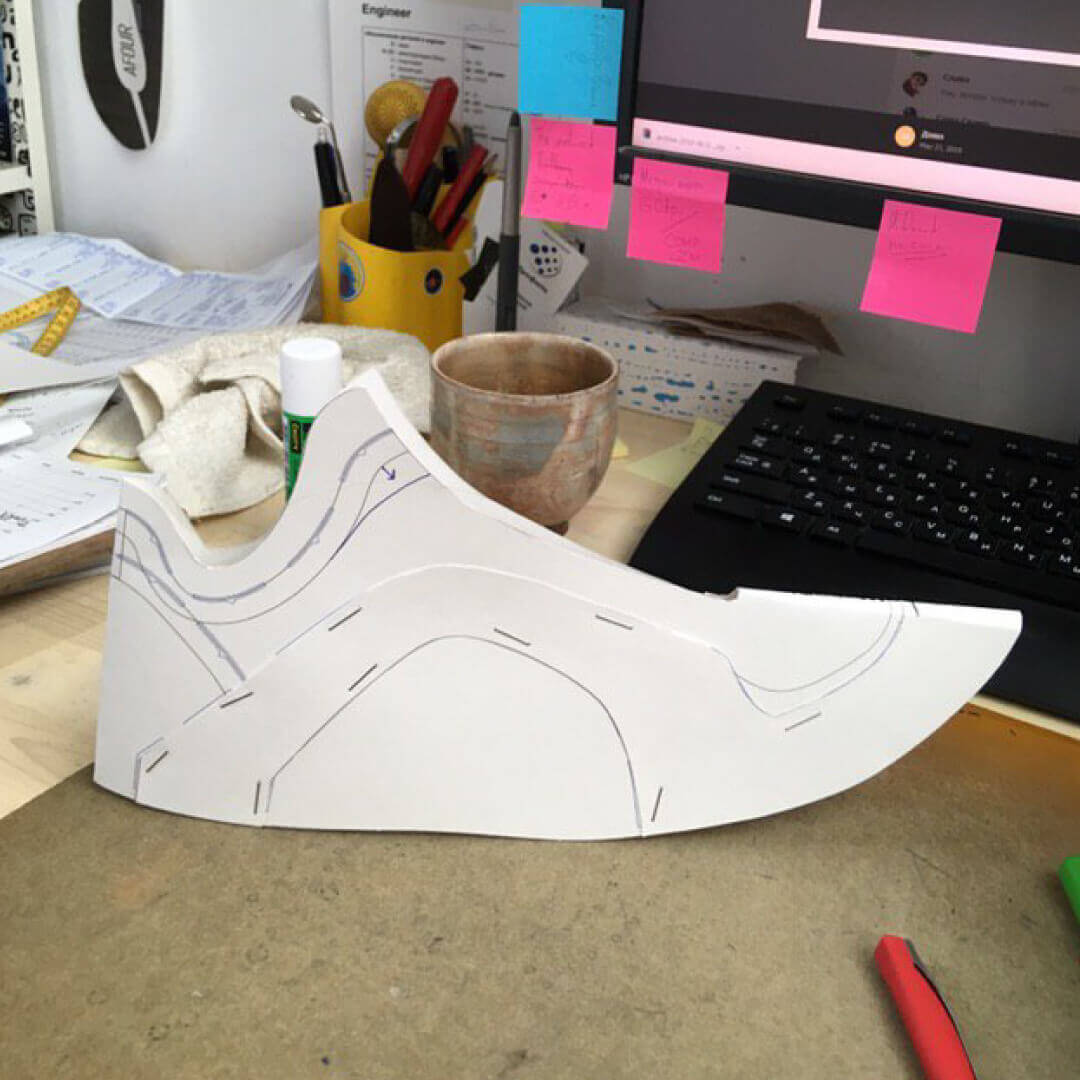

It all started with the approval of pads and technical adjustments. Before making a layout from real materials, we worked with paper. Our paper model is everything, it is very fast to manufacture, the parts are easily connected with a stapler or paper glue. The main thing is not to forget that the paper does not stretch like most shoe materials and make an amendment to this.

After agreeing on paper, we sewed the first-born to check the lines, seams and how the materials of the top interact with each other, because in addition to the usual skin, this time they used neoprene and reflective material. The first-born must be thrown onto the block, check the proportions and location of the lines. When everything is in place and the notes are made, you can adjust the last option of the patterns, determine the color palette and proceed to the main pair.

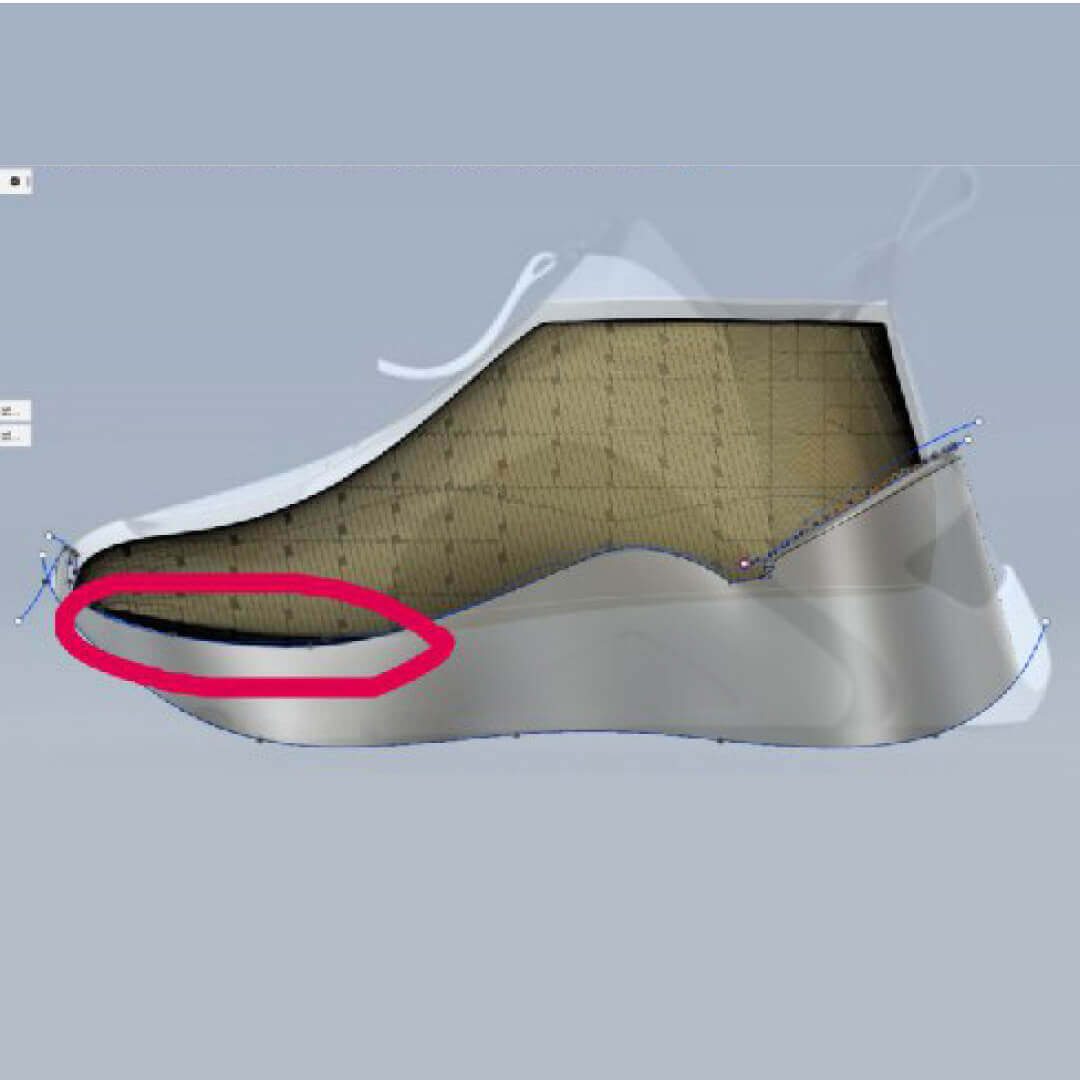

Everything takes time, especially when you do something new. Be sure to lay the buffer on unforeseen turns. So this time, not without adventure. When printing the sole, the size went two steps down and I had to gradate the patterns of the top. In addition, due to lack of time, soles were printed in parts and on different printers, and most importantly from different polymers. Therefore, as a result, one sole is purple, and the second is black. Plus, when adjusting the shape, voids came out.

Therefore, it was necessary to sand, putty, and manually choose the inner space of the sole. They did everything manually, maybe there wasn’t any time left to print a new sole - oh, these students))

That’s what happened with us.

The sneakers used a combination of fluorescent suede, reflective material, black neoprene and greased nubuck. Instead of laces in sneakers, waterproof zipper was used.

We hope more and more talented guys will develop their talent and hone their skills.